How to Choose the Right Industrial Valve Exporter for Your Business

April 29, 2025

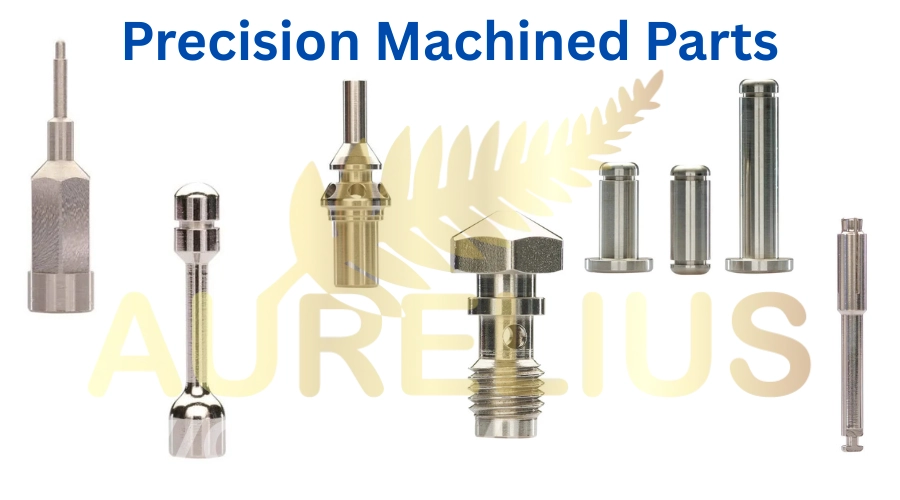

Which companies export precision machined parts from India?

June 21, 2025In today’s highly competitive industrial and manufacturing landscape, precision is not just a preference, it’s a necessity. The efficiency, reliability, and lifespan of machinery and equipment largely depend on the quality of the components used. Precision machined parts are at the core of this conversation, as they play a vital role in enhancing the overall performance of various types of equipment. From aerospace to medical devices, and automotive to electronics, industries depend on these parts for accurate and flawless functioning.

What Are Precision Machined Parts?

Precision machined parts are components that are manufactured using subtractive processes like CNC (Computer Numerical Control) machining, turning, milling, drilling, and grinding. These parts are made to exact specifications with very tight tolerances, often within microns. They are crafted from a range of materials including stainless steel, aluminium, brass, titanium, and specialized plastics.

The defining feature of precision machined parts is their accuracy and repeatability critical qualities that directly contribute to improved equipment performance.

1. Enhanced Accuracy and Consistency

One of the most significant ways precision machined parts improve equipment performance is by ensuring consistent accuracy. In high-performance machines, even the slightest deviation in a component’s size or shape can lead to errors, vibrations, or misalignments. This can affect not only performance but also safety and reliability.

By using high-precision CNC machining, manufacturers can produce components that exactly match the design requirements. These parts fit together seamlessly, reducing wear and tear and improving overall machine efficiency.

2. Reduction in Downtime and Maintenance Costs

Machines with high-quality precision parts tend to break down less frequently. Poorly made or misaligned parts can cause excessive friction, heat, or vibrations, all of which lead to premature wear or failure.

Precision machined components help eliminate these issues, resulting in reduced maintenance frequency and lower costs for repair and part replacement. Over time, this increases the uptime of equipment and boosts productivity.

3. Better Energy Efficiency

Another indirect but crucial benefit of using precision machined parts is improved energy efficiency. When parts align perfectly and operate smoothly, machines require less effort and energy to perform their functions.

For instance, in hydraulic or pneumatic systems, precision parts ensure airtight and watertight seals, minimizing energy losses due to leaks or pressure drops. Similarly, precision gears, bearings, and shafts reduce friction and energy consumption.

4. Improved Product Quality and Output

When equipment functions at optimal levels, the end product quality improves as well. Precision components allow machines to operate with high levels of accuracy, which is essential in processes like injection moulding, electronics manufacturing, and precision cutting.

The result is consistent production, fewer defects, and higher customer satisfaction. Businesses that rely on precise tolerances, such as medical or aerospace industries, cannot afford inaccuracies. Precision machined parts make it possible to maintain rigorous quality standards.

5. Customization and Flexibility

Modern precision machining technology allows for customized parts that meet specific performance goals. Whether a part requires a complex geometry, an unusual material, or specialized surface treatment, CNC machining can deliver the exact configuration needed.

This flexibility allows engineers to optimize equipment design for better performance, rather than having to work around standard parts. Tailored components also allow upgrades or modifications to existing equipment, extending their usefulness and adaptability.

6. Compatibility with Advanced Technologies

As industries move toward automation, IoT, and AI-integrated systems, precision machined parts become even more essential. Sensors, actuators, and miniature mechanical systems require parts with micro-level accuracy.

Without the tight tolerances and exact specifications achieved through precision machining, these advanced systems would fail to function as intended. Thus, precision parts are the backbone of next-generation machinery.

7. Durability and Longevity

Precision machining doesn’t just focus on dimensions. It also ensures the part’s durability. Surface finishes, material hardness, and heat resistance are all considered during the production process to maximize the part’s longevity.

By investing in precision machined parts, companies ensure that their machinery will last longer under demanding operating conditions, reducing the total cost of ownership over time.

In summary, precision machined parts are critical to the performance, reliability, and efficiency of modern equipment. By delivering accurate, consistent, and durable components, they help reduce downtime, improve energy efficiency, enhance product quality, and support advanced technologies.

For businesses that rely on machinery for production or service delivery, investing in high-quality precision machined parts isn’t just a good idea. It’s a strategic advantage. As the demand for performance and accuracy grows, so too does the importance of partnering with trusted manufacturers who can deliver components that meet the highest standards.